Written by V. Spiridonov; Originally appeared at Foreign Military Review #4 2019, translated by AlexD exclusively for SouthFront

The modular autonomous underwater vehicle (AUV) with low maintenance and operation costs allows for operational flexibility (i.e. multi-functionality), which was not available in the previous generation of AUVs, manufactured as a whole and monobloc product. Fully modular vehicles were first used in the oil and gas industry in the early 2000s. By the end of 2012, there were a significant number of them. They worked at depths of up to 1000m.

Designed fully modular commercial systems have provided a significant reduction in maintenance costs, the ability to perform new, unexpected tasks. The applied technologies have proved that AUVs can be quickly adapted to military needs. This will facilitate storage, transportation, reduce the number of maintenance specialists and the use of a variety of modular sensor units, as well as ensure the adaptation of the AUVs to actions in various water areas. The consumer can use different sources of electricity (batteries, fuel cells) in the form of modules that do not present difficulties during maintenance and replacement, as well as do not impair operational capabilities.

In addition, new sensor systems can be built into a standard module, which is then installed on the AUV, providing an expansion of their combat capabilities. This approach allows the units to be serviced at a lower cost during operation by replacing individual modules due to obsolescence and the emergence of better technologies, or changing the requirements for them, without decommissioning, while increasing their capabilities throughout its life cycle.

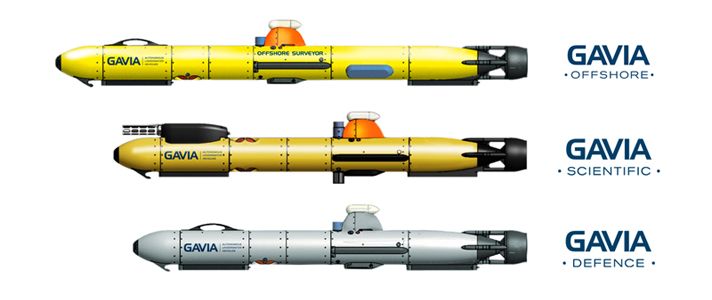

The Gavia modular vehicle was developed by Hafmynd Ltd., Reykjavik, Iceland (currently Teledyne Gavia ehf.) in the late 1990s. This was the first commercial fully modular and compact AUV capable of operating at great depth.

The basic version of the vehicle is designed as a cylinder with a diameter of 20 cm, length from 1.85 m (weight 60 kg) and up to 3.2 m (100 kg), depending on the modules used. Currently, the AUV is in service in many countries, including NATO members, and carries out mainly search tasks for mines and various objects on the bottom. In addition, it is used a s simulator for training purposes. It is adapted to the task by replacing the sensor and navigation modules.

The basic version is a set of modules that can be mounted on the ship’s deck to solve any special task, taking into account the emerging situation. The layout is accomplished by adding or removing one or more sensors, navigation aids, battery pack modules using unique connectors and interfaces.

The water impermeability is provided by two O-ring seals. In the centre of them is an electrical connector. The AUV in the standard basic configuration has a small positive buoyancy. In can operate at depths of up to 1000 m.

The fully modular concept of the AUV involves different layout options and a certain sequence of actions with the system to obtain the desired result. It is based on the following principles:

- the capabilities of an AUV are determined by the characteristics of the modules used;

- modules must be moved from one unit to another in the field without the use of special equipment;

- storage of unused modules and components on the base;

- the formation of any vehicle by combining the functional modules of the existing set;

- assembly and disassembly of the AUV is carried out using the standardised universal interface located on the functional modules.

The requirements for the AUV and module correspond to the task being performed, the length and weight of the vehicle, the number and type of modules (with battery packs), which, in turn, determine the autonomy. Gavia’s sensor capabilities depend on the selected module type.

The basic minimum version of the vehicle layout includes the nose end and a number of modules: the battery pack, control system and propulsion system.

In this layout, it has a length of 1.8 m and a weight of 50 kg. In the extended version (with the inclusion of an inertial navigation system in the AUV, multi-beam side-view sonar station, profilometer and two modules with battery packs), the length of the vehicle can be up to 3.5 m, and weigh 120 kg.

The main condition for a complete modular architecture is the presence of a standard set of interfaces designed to connect. This involves rapid development of a prototype (both the module and the vehicle as a whole) and the adaptation of various improvements within the modules and AUVs, which are combined through a standard matching interface. This means that the design and production of a series of modules is less difficult without conflict between previous modifications and that the production process of an upgraded version of the AUV can be quickly adjusted without the production and running-in of several prototypes of the vehicle, often necessary for small-scale modern production.

Moreover, the principle of modularity provides the flexibility and use of latest developments from other companies. A well-established and standardised interface (including input signals) designed for docking, power supply and data transfer allows designing and testing of sensor modules in geographically remote laboratories.

Integrated modeling systems and test benches accelerate the process of designing and implementing a promising sensor in the module in offline mode and connecting it to vehicle in the field.

Given that the modules are interchangeable, each new sample can be quickly mounted with any Gavia vehicle operated in the field. This allows a high level of technology to be maintained for sensors, energy and the ability to perform complex tasks.

As a rule, inspection and preparation of vehicles for work require significant material costs. Modularity is the way to reduce the cost of work for the customer within the life cycle of the unit, as the new generation of modules extends the life of the unit and expands its functionality. Using this principle, modules can be selected that best meet the technical and operational requirements.

Modularity makes it possible to quickly change the purpose of the AUV directly in the field by replacing and adding modules. Thus, when purchasing the basic version of the AUV designed for detecting mines in shallow waters, the side view sonar station can be reoriented to solve bathymetry issues in the presence of a bathymetric acoustic module.

Modularity allows maintenance specialists to select technologies by selecting sensors that are better suited to a specific task and match the capabilities of the data transmission system.

Emerging threats require that the AUV’s operational capabilities match them, meaning that they must have the architectural and technological flexibility to adapt to new threats and challenges.

Using this principle, service professionals can transport only those sensor modes (modules) that are required for the task, but if necessary, have additional modules in case of changing tasks. The AUV can be assembled to perform any task at the point of its application.

The dimensions of the Gavia modules make them easy to transport and store. They are placed in cases (containers) weighing from 15 to 30 kg. In the standard version, there are up to 10 containers, including shore equipment. A simplified logistics concept that allows rapid deployment and use of vehicles involves the use of conventional vehicles with a small team performing work manually, that is, without the use of complex tools and mechanisms.

In the standard version, the team consist of three specialists: an operator, a technician and a specialist in sensor modules.

The pronounced modular nature of the software allows control protocols to have a good structuring and basic scheme for the interface when planning a task. Observation models can be drawn with simultaneously developed parameters to determine its execution and installed from a single user interface. The control centre also has tools for performing system checks, initiating self-monitoring mode and quick verification of accumulated data.

A standard set of modules that provide monitoring and data collection can be installed on any Gavia AUV and allows the specialist to make a choice based on the task. This set contains modules with a side-view sonar station that registers the bottom relief, as well as modules that include video cameras. Tasks and requirements may change during work, as well as the duration of its work.

If a different set of modules is required, it can be quickly delivered to its destination and attached to any vehicle in the field at the point of application

If the duration of search operations needs to be increased, the AUV has the ability to quickly dock the additional module with the battery pack. In the standard version, the vehicle can be transported with four battery pack modules: two are installed in the AUV and two are for replacing the removed modules during the charging period (a pair of lithium-ion battery packs – 1.2 kW, 40 A – ensure the operation of the vehicle for 5-8 hours, depending on the speed and payload).

To work for 24 hours, it must have six battery packs: two for the AUV, two for replacement during the charging period of the removed ones, and two in readiness for quick replacement.

In case of damage or malfunction, the module can be quickly disassembled and replaced with a workable one, which will avoid disrupting the task.

For training and simulations, a specialised set of payload modules is used, made according to the standards approved for the AUV.

The technology used in the AUV, is developing rapidly. This applies to sensors, battery packs, propellers and control systems.

The introduction of new technologies through modularity is moving much faster and at a lower cost than in monobloc AUVs. In Gavia, the general modular interface allows for the development of new modules and thus get the next generation of vehicles. This reduces financial costs and technological risks, and accelerates the process of innovation implementation.

The development of a sonar target for sonar training for the Norwegian Navy (Sonar Training Target – SST) is an example of this.

As part of this idea, a new head end (module) was developed for Gavia.

The AUV hydroacoustic system records the received signals, amplifies them, reproduces the registered pulses, simulates the corresponding target taking into account its size and range. The system can also play back previously recorded files with the noise of submarines, openings of torpedo tubes and launches. This is used during training and evaluation of the training of surface vessels crews, and also makes it possible to train in extreme conditions in the presence of a variety of AUVs and UAVs.

The modular design provides a redundancy for retrofitting, increases the reliability and system suitability of all available AUVs. If there is a hardware malfunction in one module, it is not difficult to quickly replace it. Even if a failure occurrs on several machines, the modules can be “borrowed” from machines not involved in the operation. Their repair in the field or return to the repair facility is easy my means of simple logistics and a small footprint of one module. Its weight is 30 kg in a portable container, allowing the module to be transported by one person during transshipment and transport.

These labour costs are not comparable to the effort spent on transporting monobloc AUVs, where the entire vehicle must be transported if, for example, the sensor breaks down. The modular design affects their maintenance. It can be planned taking into account the characteristic features of the operation of individual modules within their life cycles without removing the devices from the existing ones.

This approach allows for timely replacement of AUVs and contributes to their improvement by installing new generation modules without downtime. This simultaneously reduces the financial costs of operation throughout the entire life cycle of AUVs, affects the expansion of their functionality and rapid implementation of new technologies, as well as the adaptation of vehicles to sudden needs.

A new generation of sensor modules can be included in the existing arsenal and thus will contribute to the expansion of the functionality of vehicles without creating new ones.

Modern commercial sensor modules are currently quite affordable, meet the requirements of military systems, and therefore can be used on military AUVs. In general, the modular architecture allows the operation of the vehicles for decades due to the gradual replacement of outdated modules.

The concept of full modularity is implemented in serially produced commercial products and material and technical support of the Gavia AUV, which has proven itself well in underwater coverage over the past few years, including providing short-term inspection of various engineering structures on the high seas. The basic configuration of the AUV serves as the basis for performing various operations due to a constantly updated set of modules, taking into account the tasks set.

Modular design allows the implementation with minimal effort the simplest, universal version of integration of new technologies and software, as well as the principle of “plug and play” due to a standardised physical (docking module cases), electrical (power) and bus (data transfer) interface, which allows to quickly and effectively carry out modular modernisation.

Fully modular design is most advantageous when performing military tasks. Currently, a significant number of AUVs serve several teams that perform tasks such as mine search, reconnaissance, rescue operations, sonar testing and training. In the future, it is planned to implement a strategy of continuous improvement of vehicles throughout the entire life cycle by replacing modules with more advanced ones. Increasing the flexibility of the AUVs resource base will allow to upgrade the vehicles as necessary, as well as increase their combat and functional capabilities.

Will be used to bomb Chinese ships ;)

Nice anal dildos for Xi and the great chinese communist party

inferior to the radar dolphins but more humane. good move

You Chinese and Russians think this a gigantic shark yes?

Suddenly the lids to all the torpedos fall off, surprise, surprise, and you realize the Americans STILL are showing leadership in secret warfare and assassins underwater. https://uploads.disquscdn.com/images/0179e2cf975182c6ce4234bd2d7f8c22f27d10b6211c6af273de218a1e87c431.jpg